Features

The development of a new extruder was necessitated for blow moulding of L-ring drums. L-ring drums are made of HMWHDPE having very low melt index, about 2 HLMI.

With smooth bore extruders the extrusion of HMWHDPE poses many severe problems such as uneconomical throughput, surging, excessive temperature fluctuation and attendant viscosity variations of extrudate leading to poor control of product quality and unsustainable production.

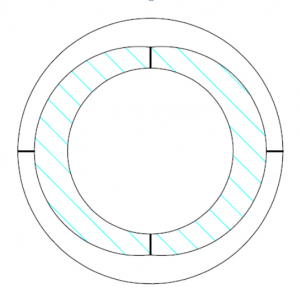

Our extruder with grooved barrel and pressure relieving system eliminates the above problems. Besides pressure relieving system, the extruder screw features good dispersive and distributive homogenisation system including multiple splitting and reorientation. An extrudate with low temperatures and adequate homogenisation is obtained.

Also the extrusion screws are tungsten carbide coated. The coating is full encapsulation throughout. The benefit is a lot longer service life with little loss of throughput.

Revolutionizing Blow Moulding with Indigenous Innovation

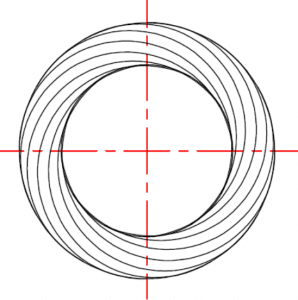

One of the biggest challenges in blow moulding HMWHDPE (High Molecular Weight High-Density Polyethylene) is the weakening of wall thickness in weld line regions due to viscoelastic effects. This occurs where divided melt streams recombine, forming weakened areas in the parison.

To address this issue, the overlapping flow accumulator head has been widely adopted. While effective in reducing weld line problems, it does not fully eliminate them.

A Simpler, Smarter Solution: Spiral Mandrel Distribution

To completely eliminate weld line issues, Mr. S.T. Sekharan pioneered the spiral mandrel distribution system in blow moulding. This innovation enhances performance by ensuring:

- Uniform wall thickness distribution across the parison.

- Elimination of weld lines, resulting in articles with superior hoop strength.

- Improved production stability and consistent quality, simplifying machine operation.

As the first manufacturer in India to offer this technology, we are transforming blow moulding with unparalleled efficiency and cost savings.

World-Class Performance, Cost-Effective Solution

Our machines deliver performance comparable to imported systems, with added advantages:

- Superior article quality

- Lower energy consumption

- Reduced maintenance requirements

- Ease of operation and setup

Advantages at a Glance

- Enhanced Strength: Superior drop strength, hoop strength, and top-load strength.

Example: A 200-litre L-ring drum (8.2 kg) achieves a top-load strength of 1800 kg. - Raw Material Savings: Precise weight control reduces raw material usage and increases profitability.

Example: Weight variation for a 200-litre L-ring is ±20 grams. - Quick Colour Changes: Save raw material, energy, and production time with faster transitions.

- Lower Rejection Rates: Maintain rejection rates under 1% for maximum efficiency.

- FIFO System: First-In-First-Out (FIFO) system ensures that raw material degradation is prevented and consistent parison ejection. Excellent quality articles are produced with least rejections.

- Precision Performance: Produces straight parisons with uniform wall thickness.

- Durable Components: Melt contact parts are made from EN41B nitriding steel, ensuring longevity and wear resistance.

- Improved Cooling: Uniform wall thickness reduces cooling time and energy consumption.

- Higher Uptime: Reliable extruder, hydraulic, and pneumatic systems ensure continuous operation.

- Retrofit Capability: Upgrade existing machines for superior performance and efficiency.

Retrofitting Options for Existing Machines

This cutting-edge technology can be retrofitted onto other machines to solve key challenges, such as:

- High power consumption

- Unstable output

- Inconsistent product quality

- Excess raw material wastage

- Prolonged colour change times

Ready to Transform Your Production?

Upgrade your blow moulding process with our innovative solutions. Whether you’re investing in a new machine or retrofitting an existing one, we can help you achieve superior quality, efficiency, and cost savings.

Contact us today to explore how we can optimize your operations!