Features

The development of a new extruder was necessitated for blow moulding of L-ring drums. L-ring drums are made of HMWHDPE having very low melt index, about 2 HLMI.

With smooth bore extruders the extrusion of HMWHDPE poses many severe problems such as uneconomical throughput, surging, excessive temperature fluctuation and attendant viscosity variations of extrudate leading to poor control of product quality and unsustainable production.

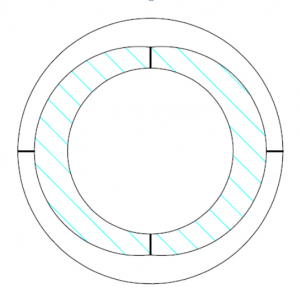

Our extruder with grooved barrel and pressure relieving system eliminates the above problems. Besides pressure relieving system, the extruder screw features good dispersive and distributive homogenisation system including multiple splitting and reorientation. An extrudate with low temperatures and adequate homogenisation is obtained.

Also the extrusion screws are tungsten carbide coated. The coating is full encapsulation throughout. The benefit is a lot longer service life with little loss of throughput.

Manufacturing of 200 litre capacity L-ring drums made of HMWHDPE having HLMI value 2, were produced in India on imported blow moulding machines. For the first time in India we introduced IFC blow moulding machines with overlapping flow accumulator head under the brand name VINITHA so that 200 litre L-ring drums could be manufactured indigenously. The overlapping flow accumulator head mitigates the adverse reduction of wall thickness in weld line regions. It is a severe problem in blow moulding especially when the polymer processed is High Molecular Weight High Density Polyethylene ((HMWHDPE) having High Load Melt Index value about 2. Owing to viscoelastic effects, considerably weakened regions are formed in the parison where the divided melt streams recombine.

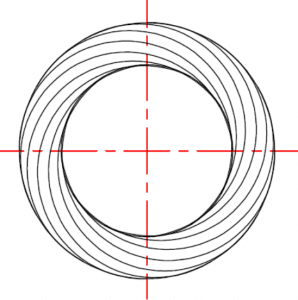

In order to eliminate weld lines altogether, Mr. S.T.Sekharan found a simpler solution, the spiral mandrel distribution of melt flow in blow moulding – accumulator head.The new accumulator head with spiral mandrel distributor gives excellent performance. No other manufacturer in India offers this type of accumulator head for blow moulding. After its introduction the machine performance in terms of quality and production efficiency has significantly increased. The operator is able to set the machine very easily. The operation of the machine is very stable and consistent production is achieved.Though the performance of these machines are comparable to imported ones the machines are far cheaper and are very low on energy consumption than imported machines.

Advantages

1. Even circumferential wall thickness distribution of parison

2. Elimination of weakening weld lines (increased hoop strength of article that is subjected to internal pressure)

3. Broad processing range (change in material, throughput, operating point)

4. Very fast colour change. It means less wastage of raw material and a lot of energy saving.

5. Gives good, straight parison without curl

6. Even temperature distribution; hence faster cooling of articles manufactured in our machine. This also reduces residual stresses developed in the article due to uneven cooling. (greater drop strength)

7. Suitable for multilayer heads too. Three layer accumulator heads for IFC blow moulding machines upto 2000 litre capacity has been developed. Larger ones are under development.

8. Less maintenance

9. Least rejection rate of articles (saving of raw material and energy)

10. Stable performance of the IFC blow moulding machines.